This one will warrant a little background, specifically with regard to how hazards are managed in occupational contexts. The most obvious first step is for the employer to assess their processes to determine if there are hazards to workers. Hazards come in a variety of forms, including mechanical (caught-in, struck-by, etc.), chemical (corrosives, flammables, etc.), health (toxins, asphyxiants, etc.), and such. Performing a Job Hazard Analysis allows the employer to identify all hazards present in a process.

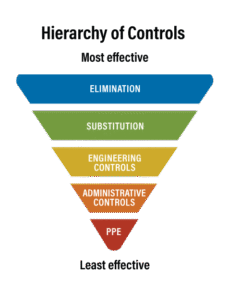

Once the hazards are identified, it is the employer’s responsibility to consider how to control those hazards to prevent workers from being injured or killed and prevent damage to process equipment. Below is a diagram showing the hierarchy of hazard control methods.

The most effective method for controlling a hazard is to eliminate it entirely. Does the process really require the use of a toxic, caustic, highly flammable substance that generates a hazardous waste as a byproduct? Could the step of a process where a worker has to climb bodily into a piece of equipment be avoided entirely? If a hazard can be eliminated, it should be.

The next most effective method is substitution of the hazard with a non-hazardous or less hazardous alternative. Does it have to be a strong acid bath or can the process step utilize a weaker acid or a non-acidic bath? The point is to dial down the hazard to the point that workers exposure is as limited as possible.

Engineering controls come next. These are physical conditions designed to separate workers from hazards. If the hazard cannot be eliminated or substituted away, guarding and isolation can protect workers from being exposed to it. Machine guarding prevents moving parts from harming workers. Barriers and ventilation (like a fume hood) prevent workers from being exposed to chemical hazards. Isolation involves putting adequate space between workers and hazards, like placing dangerous machinery in a separate, sealed area.

Administrative controls include things like signage, training, area markings, alarms, and the like. These are only effective if the employer uses them in the right locations and the workers understand them.

Lastly, we get to the meat of this question: personal protective equipment (PPE). PPE is the least effective method for hazard control. It is the last line of defense and the weakest. Gloves, goggles, respirators, etc. all provide a barrier between a worker and a hazard, but that barrier is dependent upon proper selection, proper design, proper manufacturing, proper use, proper cleaning, and proper maintenance. In a scenario where an employer deems that the hazard cannot be eliminated or substituted away and determines that the engineering and administrative controls still leave workers exposed to hazards, that employer must select personal protective equipment that is properly designed to prevent the hazard from injuring the workers. That PPE must be rated and tested for the purpose it is selected for (a dust mask cannot be selected as a respirator for use with chemical fumes). The PPE must be provided by the employer, along with training in its use.

OSHA’s requirements for personal protective equipment can be found at 29 CFR Part 1910 Subpart I. The requirement for employers to identify and assess hazards to determine PPE needs is at §1910.132(d), which states:

(d) Hazard assessment and equipment selection.

(1) The employer shall assess the workplace to determine if hazards are present, or are likely to be present, which necessitate the use of personal protective equipment (PPE). If such hazards are present, or likely to be present, the employer shall:

(i) Select, and have each affected employee use, the types of PPE that will protect the affected employee from the hazards identified in the hazard assessment;

(ii) Communicate selection decisions to each affected employee; and,

(iii) Select PPE that properly fits each affected employee.

Note: Non-mandatory appendix B contains an example of procedures that would comply with the requirement for a hazard assessment.

(2) The employer shall verify that the required workplace hazard assessment has been performed through a written certification that identifies the workplace evaluated; the person certifying that the evaluation has been performed; the date(s) of the hazard assessment; and, which identifies the document as a certification of hazard assessment.

So, we’ve pretty well covered that employers are the ones responsible to identifying when PPE will be required, selecting the appropriate PPE, and ensuring that the PPE properly fits the employees required to use it. The employer is also responsible for providing training on when PPE is required, what PPE is required, how to wear the required PPE, the limitations of the PPE, and the care and maintenance of the PPE. But—finally getting around to the answer for your question—what about the cost?

Let’s take a look at §1910.132(h).

(h) Payment for protective equipment.

(1) Except as provided by paragraphs (h)(2) through (h)(6) of this section, the protective equipment, including personal protective equipment (PPE), used to comply with this part, shall be provided by the employer at no cost to employees.

(2) The employer is not required to pay for non-specialty safety-toe protective footwear (including steel-toe shoes or steel-toe boots) and non-specialty prescription safety eyewear, provided that the employer permits such items to be worn off the job-site.

(3) When the employer provides metatarsal guards and allows the employee, at his or her request, to use shoes or boots with built-in metatarsal protection, the employer is not required to reimburse the employee for the shoes or boots.

(4) The employer is not required to pay for:

(i) The logging boots required by 29 CFR 1910.266(d)(1)(v);

(ii) Everyday clothing, such as long-sleeve shirts, long pants, street shoes, and normal work boots; or

(iii) Ordinary clothing, skin creams, or other items, used solely for protection from weather, such as winter coats, jackets, gloves, parkas, rubber boots, hats, raincoats, ordinary sunglasses, and sunscreen.

(5) The employer must pay for replacement PPE, except when the employee has lost or intentionally damaged the PPE.

(6) Where an employee provides adequate protective equipment he or she owns pursuant to paragraph (b) of this section, the employer may allow the employee to use it and is not required to reimburse the employee for that equipment. The employer shall not require an employee to provide or pay for his or her own PPE, unless the PPE is excepted by paragraphs (h)(2) through (h)(5) of this section.

(7) This paragraph (h) shall become effective on February 13, 2008. Employers must implement the PPE payment requirements no later than May 15, 2008.

Note to § 1910.132(h): When the provisions of another OSHA standard specify whether or not the employer must pay for specific equipment, the payment provisions of that standard shall prevail.

The employer is, with a few exceptions, required to provide PPE “at no cost to employees”. What are the limitations? In (h)(2) we see that non-specialty footwear and non-specialty prescription eyewear are excluded, if the employer allows them to be worn off the job-site. So, if your employer requires that you wear general safety-toe boots and does not permit you to wear them off the job-site, they are responsible for covering the cost of that footwear. If, on the other hand, they allow the boots to be worn off the job-site they are not required to cover the cost. At (h)(4) we see that ordinary clothing and everyday wear are required to be covered by the employer. If an employee chooses to supply their own PPE, the employer is not required to reimburse the employee for the cost of the equipment but is required to ensure that the employee-supplied PPE is adequate for the hazards present and is properly maintained and sanitized.

If you choose to use PPE that is not required by your employer, you will be responsible for the cost. As an example: If you work in an area where noise levels are not above the permissible exposure limits, your employer will not be required to provide hearing protection. You have the freedom to purchase and use hearing protection anyway, but you will be responsible for covering the cost.